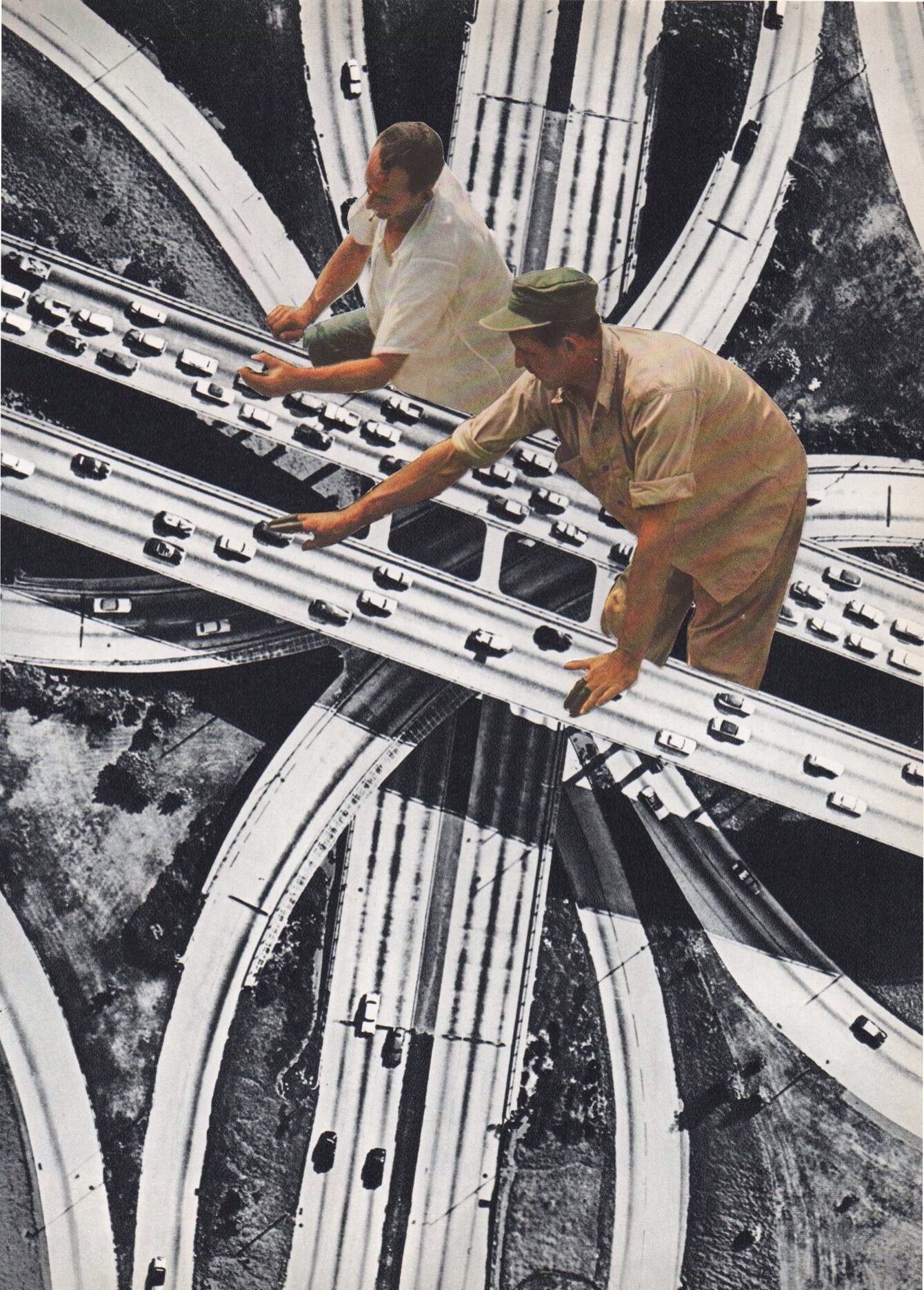

Today a friend of mine from Nagasaki mentioned ‘genchi genbutsu’ over coffee. I had never heard of it. Genchi Genbutsu is a Japanese management method that translates to ‘actual place, actual thing’. It means managers are expected to be surgically on top of the operational realities of the ‘engine room’ by being physically present when the most crucial decisions are made.

The Japanese now consider it a philosophy as much as a management principle.

Toyota appears to be the most devoted. The Chicago Sun-Times ran an article in 2004 offering a detailed example. When Toyota engineer Yuji Yokoya was tasked with re-engineering a fresh version of the Toyota Sienna minivan for the American market, he drove one over 40,000 miles across America, from Alaska down to the Mexican border and from Florida to California.

As the paper described it: ‘Crossing the Mississippi River by bridge, Yokoya noted that the Sienna’s crosswind stability needed improvement. He observed excessive steering drift while traversing gravel roads in Alaska, and the need for a tighter turning radius along the crowded streets in Santa Fe. Driving through Glacier National Park, he decided the handling needed to be crisper. He also made an all-wheel-drive option a priority, along with more interior space and cargo flexibility.

Finally, he decided that the new Sienna would have to be a minivan that families, and especially kids, could live in for extended periods of time. Upgrading seat quality became a priority, along with “kid-friendly” features such as a roll-down window for second-row passengers, an optional DVD entertainment centre and a conversation mirror so parents could monitor what was going on in the back seat.’